How Food Producers Use Barcode Labels to Stay Compliant

In the world of food production, compliance isn’t optional - it’s baked into every step of the process. From the farm to the fork, producers are expected to meet strict standards that ensure product safety, traceability, and transparency. And when the FDA, USDA, or a retail partner comes knocking, your barcode labeling system better be airtight.

Barcode labels aren’t just helpful for inventory… they’re essential for compliance.

Failing to follow labeling regulations can result in serious consequences:

Product recalls

Fines and legal penalties

Damaged relationships with distributors and retailers

Loss of consumer trust

Let’s break down exactly how food producers use barcode labels to stay compliant, and how your business can do the same.

The Role of Barcode Labels in Staying Compliant

Barcode labels aren't just for warehouse shelves. In the food industry, they’re a vital part of operational integrity. Here’s what they help with:

✅Traceability

Track ingredients and final products through every phase, from raw material intake to final packaging. Lot and batch numbers embedded in barcodes allow fast lookup if a recall occurs.

✅Real-Time Recordkeeping

Barcode scanning automates data entry, reducing human error and generating accurate logs for audits, inspections, and inventory reports.

✅Shelf Life + Expiration Tracking

Labels can include production dates, best-by dates, and use-by info. Barcode scanning systems can flag outdated stock before it reaches the customer.

✅Recall Readiness

If something goes wrong, barcode tracking allows you to isolate the issue, locate affected batches, and act fast, often within hours, not days.

✅Retail + Wholesale Compatibility

Meeting compliance isn’t just about regulations, it's about your buyers. Retailers often require GS1-compliant barcodes or specific formats like UPC, EAN, or QR codes to accept your product.

What Labels Must Include to Stay Compliant

Depending on what you produce, your barcode label may need to include:

Product name and variant (e.g. “Spicy Garlic Pickles”)

Ingredients list + FDA-mandated allergen disclosure

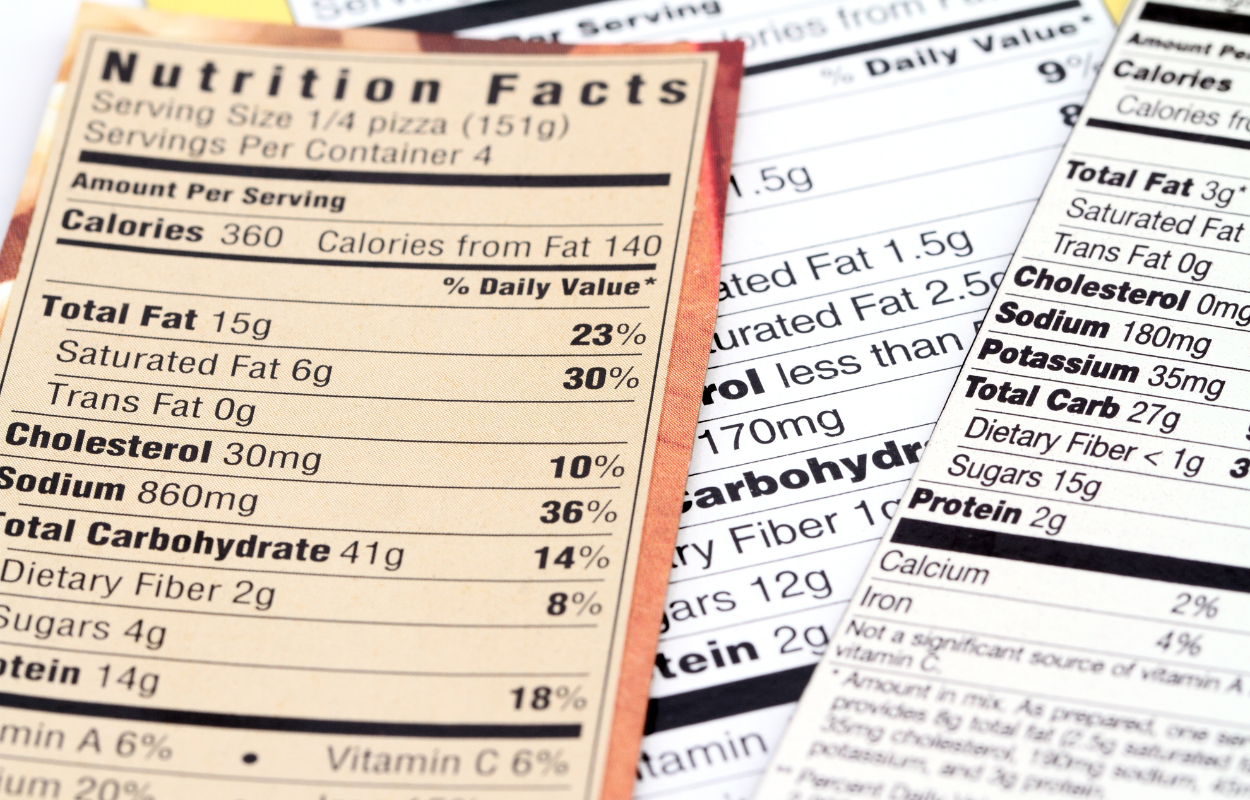

Nutritional facts (if applicable)

Lot/batch number and production date

Expiration date or best-by date

Handling or storage instructions

Scannable barcode (UPC, GS1-128, QR, etc.)

Labels must be legible, smudge-proof, and securely affixed to the container, no fading or falling off, even in cold or damp conditions.

Special Considerations: Labels for Cold Storage & Moist Environments

Here’s something that makes food compliance labeling unique: the environment.

Your labels need to survive refrigerators, freezers, condensation, and sometimes heat. That means:

Waterproof label stock (polypropylene or polyester)

Food-safe adhesives that don’t peel or contaminate

Thermal transfer printing with resin ribbon for maximum durability

Even if your product looks great at room temp, it won’t matter if the label falls off after two days in the fridge.

Recommended Labeling Tools for Food Producers

To stay compliant and efficient, producers should invest in:

Labeling software with template libraries and regulatory formatting (like BarTender)

Durable labels compatible with food-safe packaging and cold environments

Reliable printers that support high-volume output and clear barcode printing

Pro Tip: Use Zebra Temperature Indicators to Protect Perishable Food

Cold chain breaks can lead to spoiled product and safety risks. Zebra Temperature Indicators offer a simple way to track temperature-sensitive food during storage and shipping.

How they help:

✅ Stick directly to packaging - Easy to apply to boxes, pallets, or containers

✅ Preset thresholds - Choose indicators matched to your product’s safe range

✅ Color-change alerts - Instantly shows if temps go out of range

✅ No tools needed - Just a quick visual check — no scanners required

✅ Stay compliant - Helps meet FDA and food safety standards

Protect your product and reputation with a smart, low-cost solution.

Be Audit-Ready Year Round

Many food producers wait until an audit is scheduled to organize their label data, and that’s a mistake.

Your barcode labeling system can also serve as a compliance audit tool, tracking:

Who labeled each batch

When it was labeled

What printer or system was used

What product it was assigned to

That kind of documentation can turn a stressful audit into a fast formality.

Have questions about staying compliant? Fill out the quick form below or contact us here and one of our experts will help you!