Automating Your Labeling Process: Printers, Dispensers, and Applicators Explained

Labeling is one of the most overlooked yet critical parts of business operations. Done manually, it can slow production, introduce costly errors, and create bottlenecks on the floor. That is why many companies turn to CAB labeling solutions, trusted worldwide for precision, durability, and versatility.

Instead of treating labeling as just another step in the process, think of it as an opportunity to transform efficiency across your operation. Let’s take a closer look at label printers, dispensers, applicators, and shrink sleeve printers, and how each one can change the way you work.

Why Automate Your Labeling Process?

Save time by reducing manual handling

Lower labor costs by streamlining repetitive tasks

Improve accuracy and consistency for compliance and brand integrity

Scale up production without adding extra staff

Label Printers: The Foundation of Automation

Label printers are where automation begins. They give you high-quality labels on demand, whether you are producing product packaging, shipping labels, or compliance tags.

Use Case Example

A mid-sized cosmetics brand needed to manage hundreds of SKUs with varying label sizes. By implementing automated label printing, they eliminated errors caused by pre-printed rolls and reduced material waste by 15 percent.

Industries That Benefit

Retail and e-commerce (product and shipping labels)

Healthcare (compliance labels, specimen tracking)

Manufacturing (parts, safety, and compliance labels)

Label Dispensers: Semi-Automated Efficiency

Dispensers peel and present labels for operators, speeding up application without requiring a fully automated system. This is ideal for businesses looking for efficiency without the investment of an applicator system.

Use Case Example

A food packaging company supplying fresh deli items adopted label dispensers to speed up daily labeling for expiration dates. The change cut application time in half while reducing operator fatigue.

Industries That Benefit

Food and beverage

Warehousing and logistics

Small-batch manufacturing

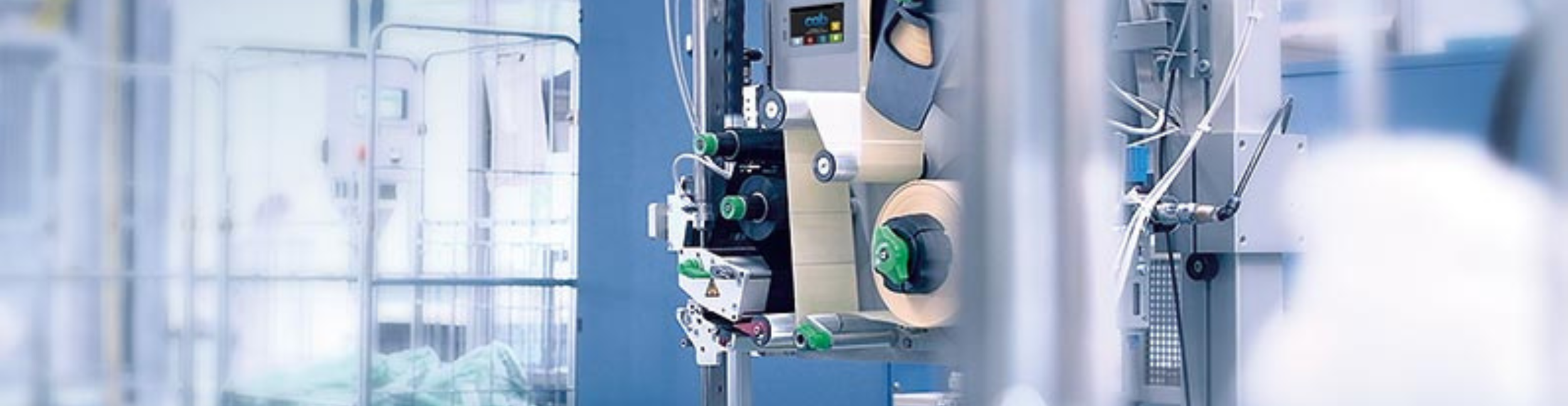

Label Applicators: Full Automation in Action

Applicators are built to integrate directly into production lines, applying labels automatically to products, cases, or pallets. They are the top choice for high-volume operations where speed and precision are critical.

Use Case Example

An electronics manufacturer added automated applicators to its conveyor system. This eliminated manual errors, boosted throughput by 30 percent, and ensured labels aligned perfectly every time.

Industries That Benefit

Automotive and electronics manufacturing

Pharmaceuticals

Consumer packaged goods

Shrink Sleeve Printers: Maximum Coverage and Durability

Shrink sleeve printers create full-coverage labels that wrap entirely around containers. They are ideal for products exposed to moisture, abrasion, or temperature changes.

Use Case Example

A beverage company switched from pressure-sensitive labels to shrink sleeves to improve shelf appeal and durability in refrigerated environments. The new system not only improved branding space but also reduced returns due to peeling labels.

Industries That Benefit

Beverage and alcohol

Health and beauty

Household cleaning products

Ask our team! Fill out the quick form below or contact us here, and one of our CAB experts will help you!