When You Should Not Buy a 600 DPI Industrial Printer

In the world of industrial label printing, “higher DPI” is often assumed to mean “better.” And while 600 DPI printers absolutely have their place, they are frequently oversold, misunderstood, and misapplied.

In reality, a 600 DPI industrial printer is a specialized tool. Buying one without a clear reason can lead to higher costs, slower print speeds, unnecessary complexity, and zero improvement in scan performance or label quality.

This guide breaks down when you should not buy a 600 DPI industrial printer, when you actually should, and what you should consider instead.

But first…

What 600 DPI Really Means

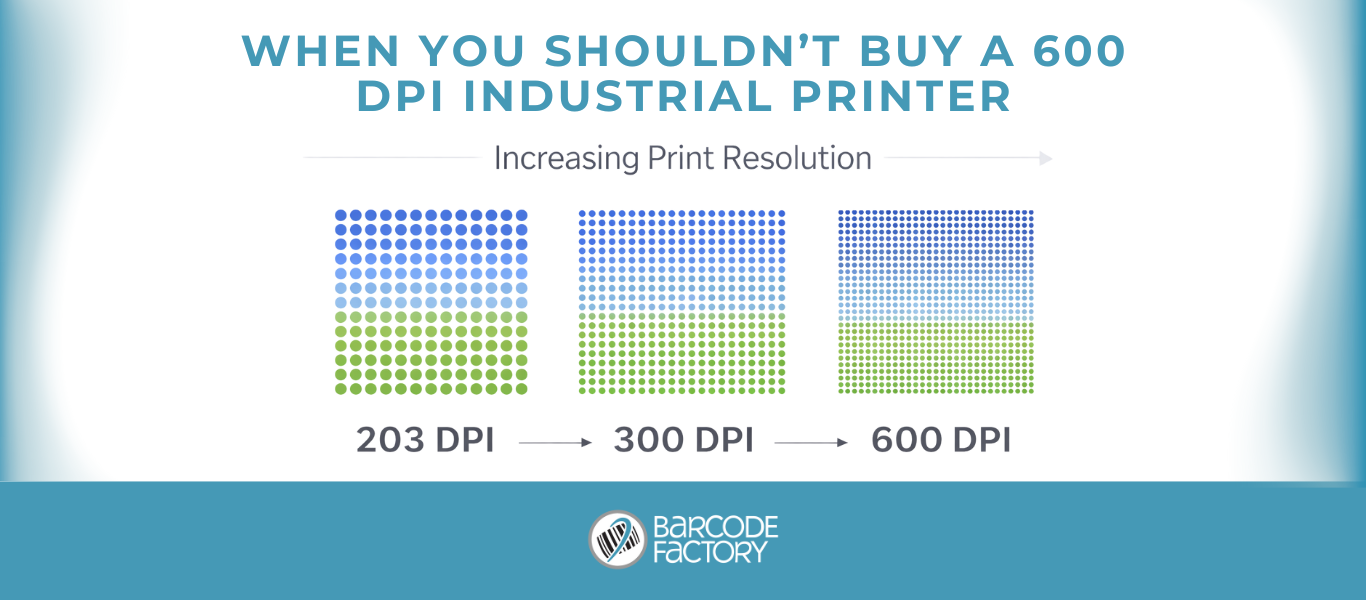

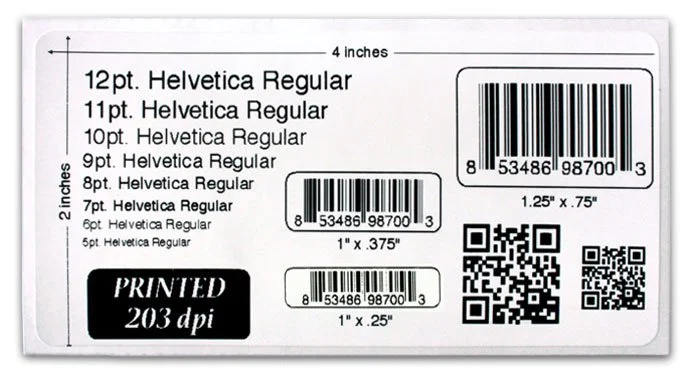

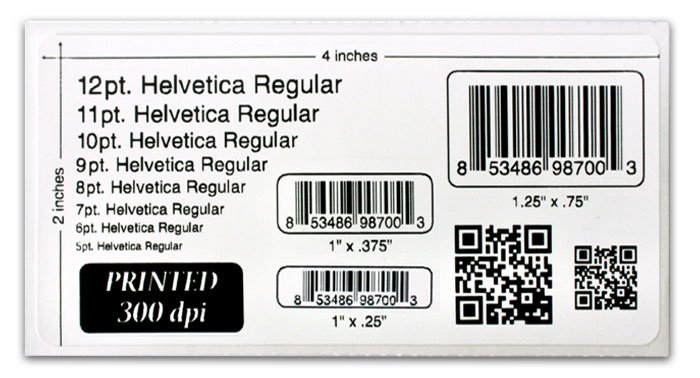

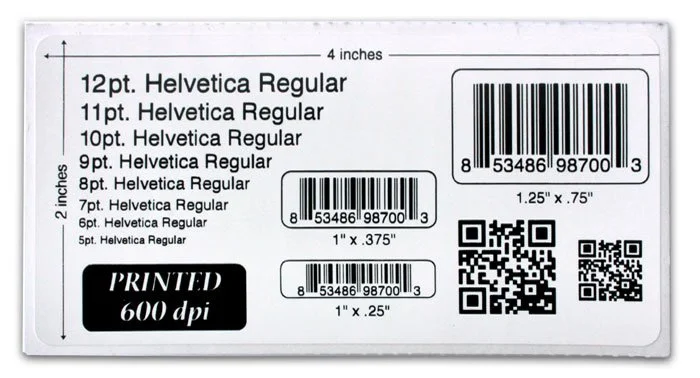

DPI (dots per inch) refers to print resolution. A 600 DPI printer places twice as many dots per inch as a 300 DPI printer, and four times as many as a 203 DPI printer.

That extra resolution:

Helps with very small text

Improves fine line clarity

Sharpens dense or complex barcodes

Supports highly detailed graphics

Scenarios Where You Should NOT Buy a 600 DPI Printer

If any of the following describe your operation, a 600 DPI printer is likely unnecessary or even counterproductive:

Printing shipping labels, carton labels, or pallet labels

Printing 4x6 or larger labels

Printing standard 1D or 2D barcodes at normal sizes

Operating in warehousing, distribution, or logistics

Printing product labels without micro-text

Printing labels that are viewed from arm’s length or farther

Running high-volume or high-speed print jobs

Replacing an older 203 or 300 DPI printer that worked fine

Trying to “future-proof” without a real use case

Buying based on “higher number = better”

In these scenarios, the extra resolution simply isn’t being used.

Why a 600 DPI Printer Is Often the Wrong Choice

1. Higher Cost With No Functional Gain

600 DPI printers cost more upfront, and replacement printheads are significantly more expensive. If the application doesn’t demand that resolution, the ROI simply isn’t there.

2. Slower Print Speeds

Higher resolution means more dots to fire. Many 600 DPI printers run at slower maximum speeds, which can bottleneck production lines or fulfillment operations.

3. Tighter Tolerances and Setup Sensitivity

600 DPI printing requires:

Better label materials

Cleaner environments

More precise calibration

More frequent maintenance

Dust, ribbon wrinkles, or minor alignment issues that wouldn’t matter at 300 DPI can cause visible defects at 600 DPI.

4. No Barcode Scan Advantage in Most Use Cases

Barcodes do not become “more scannable” just because they’re printed at higher resolution. In fact, oversized resolution can sometimes reduce contrast or cause edge definition issues if media and ribbon aren’t perfectly matched.

5. Overkill for Industrial Environments

Most industrial labeling is about:

Durability

Consistency

Throughput

Reliability

Resolution beyond 300 DPI rarely improves any of those.

Industries That Usually Do NOT Need 600 DPI

These industries almost always perform better with 203 or 300 DPI printers:

Warehousing and distribution

Third-party logistics (3PL)

Manufacturing and work-in-process labeling

Shipping and fulfillment centers

Food and beverage logistics

Retail back-of-house operations

Asset tracking and inventory labeling

Compliance labeling where text is readable but not microscopic

In these environments, clarity at normal viewing distance matters far more than microscopic sharpness.

What You Should Buy Instead (In Most Cases)

For the vast majority of industrial label applications, these options deliver better results, better reliability, and better value.

203 DPI Industrial Printers

OUR RECOMMENDATION: Printronix T4000

For high-volume labeling where speed and reliability matter more than ultra-fine detail, the Printronix T4000 203 DPI industrial printer is built to perform day in and day out. It’s a strong choice for shipping, warehouse, and logistics environments that need fast output, durable construction, and consistent barcode performance.

Best for:

High-volume shipping labels

Large format labels

Warehouse and pallet labeling

Fast throughput environments

Benefits:

Faster print speeds

Lower consumable costs

Longer printhead life

Extremely reliable scanning

300 DPI Industrial Printers

OUR RECOMMENDATION: The Zebra ZT231

If you want high-quality 300 DPI output with room to grow, the ZT231 hits the sweet spot between performance and price. With touchscreen operation, robust connectivity, and optional upgrades like RFID and wireless, it covers the majority of real-world labeling needs without overbuying resolution.

The true “sweet spot” for most operations.

Best for:

Product labeling

Medium-density barcodes

Smaller labels without micro-text

Applications needing sharper text but not extreme detail

Benefits:

Excellent balance of clarity and speed

Widely compatible with media

Strong scan performance

Lower cost than 600 DPI with most of the benefits

When You Should Buy a 600 DPI Industrial Printer

Now, let’s be clear: 600 DPI absolutely has a place. You just need a real reason.

You should strongly consider a 600 DPI printer if you are dealing with any combination of the following:

Extremely Small Labels

If your labels are physically small and must contain a lot of information, higher resolution becomes critical.

Examples:

0.5” x 0.5” or smaller labels

Micro-labels for electronics

Compact pharmaceutical containers

Very Small Text

If your label requires:

Fine legal disclaimers

Dense ingredient lists

Multi-language text blocks

Human-readable text under 4–5 pt size

600 DPI may be the only way to keep text legible.

High-Density Barcodes

Certain barcodes require extremely fine module widths.

Examples:

Dense DataMatrix codes

High-density QR codes on small labels

Barcodes printed near minimum size tolerances

High-End Product Labeling

If branding and visual precision matter at close inspection, higher DPI can help.

Examples:

Cosmetic packaging

Specialty health products

Premium retail goods

Boutique or luxury labeling

Regulatory or Compliance Requirements

Some industries require labels that remain readable under magnification or strict inspection.

Examples:

Pharmaceuticals

Medical devices

Laboratory sample labeling

Electronics and components

If You Do Need a 600 DPI Industrial Printer…

OUR RECOMMENDATION: The Zebra ZT411

The Zebra ZT411 600 DPI industrial printer is built for applications that demand extreme precision, making it ideal for micro text, dense barcodes, and high-detail labeling where lower resolutions fall short. With advanced connectivity, field-upgradable options, and Zebra’s Print DNA platform, it delivers long-term reliability for specialized, high-resolution environments.

The right choice is not about the highest number. It is about the right tool for the job. If you still aren’t sure which option is the right choice for you, we make it simple, fill out the quick form below, and our printer experts will guide you to the right choice!