The Future of Retail Barcoding

From little white price stickers in the 1950's, to 1D barcodes, to more information.

The need for more information on product packaging is the driving force in retail point-of-sale and other industries. The standard UPC barcode, which has been used since 1972, contains only pricing information (GTIN® Global Trade Item Number) associated with the product as well as the manufacturer.

Added information at the product level will improve many others parts of the supply-chain. The question is how to achieve this. The answers include some upgrades to scanning equipment, but mostly the software and increased data streams.

When will this transformation take place?

The simple answer is over the next few years and likely in 2027. Research conducted by GS1, released in February 2020, shows the retail sector at large does not currently have the equipment to implement this next-generation of product identification. GS1 US will be a driving force behind this change. In May of 2020 GS1 began the Sunrise initiative to support adoption of 2D barcodes at Point-of-Sale.

Research of Brand owners and Retailers, shows that they have begun phasing out linear scanners and installing new 2D optical scanners that can read dynamic data and fixed data. Retail upgrades look to continue up to 2027.

What's to be gained?

Dynamic data vs Static Data

Static data in the current UPC-A barcode lists only price. The retailers’ data carrying software sees the company identifier GTIN, and can change the value/price on that item on their store software. Dynamic data is product information that is rich and based on time elements. This data must be captured by scanning one of three 2D barcodes: Data Matrix, GS1 DataMatrix or QR code.

Multiple lines of information including:

GTIN Trade Number batch/lot number, Serial Number, Production Date, Packaging Date, Best Before Date, Expiration Date, Count of Items, Net Weight, Pounds, and Applicable Amount Payable (price).

The improvements:

for the retailer, brand owner and inevitably the manufacturer is a source of shared information that will improve multiple processes for all involved companies. These include:

Inventory Accuracy

Improved Consumer Engagement

Product Authenticity will help reduce counterfeit goods.

Traceability for deeper product control, distribution and more.

Freshness/ Waster Prevention

Returns Management

Variable Measure Trade Items

What the final transformation will look like.

The global standard for barcoding in the future will be based on multiple GS1 AI Application Identifiers that are able to capture and carry data from multiple barcode types. These newly developed AI Application Identifiers will be able to read a variety of barcodes.

Currently, the only 2D barcode that can be used at OPOS is the DataMatrix for variable-measure fresh food and only with partner agreements.

What the future holds is a migration towards complete 2D barcodes and scanning. As of the beginning of 2021 only UPC-A barcodes are being used. Between now and 2027 the addition of 2D barcodes will be added to the UPC static barcodes. After 2027, products will contain either the UPC barcode only or the 2D barcode. Keep in mind, human-readable information will still be required.

Conclusion

Exploring more detailed information directly from GS1 Advanced Data Carrier for POS is a good place to start.

This collaboration between Brand Owners and Retailers. It can be broken down into five steps:

Conclusion

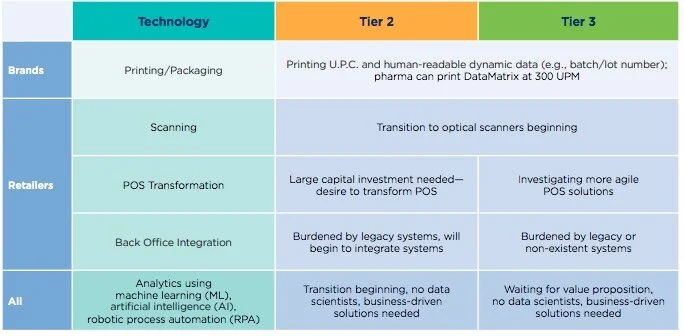

Printing and Packaging – lines may require capital investment to print dynamic 2D barcodes. The pharmaceutical industry has been printing and encoding GTIN and attribute-data in the GS1 DataMatrix barcode on their regulated products for several years.

Scanning – The majority of retailers today use linear, or laser, POS scanners that can only read 1D barcodes. The replacement of in-counter linear or laser scanners may only require scan engine replacements. Handheld scanners typically have a 5-year lifespan so replacing them with optical 2D imagers will be a less painful transition.

POS Systems – POS systems need to be able to ingest the GTIN and associated attribute data. Tier 1 is already upgrading POS—mostly due to the requirements of omnichannel commerce and mobile POS. Tier 2 is generally burdened with legacy systems—however, omnichannel commerce is an expectation for all retailers, and they need to modernize their systems. Some Tier 3 retailers are the most agile, with cloud-based POS systems already implemented, while others struggle with budgets and older infrastructure.

Backend Systems – This new and larger input of scanned data must be integrated into backend systems, such as inventory, supply chain management and merchandising systems. Integration is complex, and this appears to be the most significant bottleneck in the industry.

Analytics – The industry needs technical solutions to make data analytics automated and actionable. There is a tremendous opportunity for brand owners and retailers to share data and insights and to strengthen their partnership.

For fast and productive answers to all your questions Contact a Barcode Factory Representative