Near-Edge and Flat Head Thermal Transfer Printing

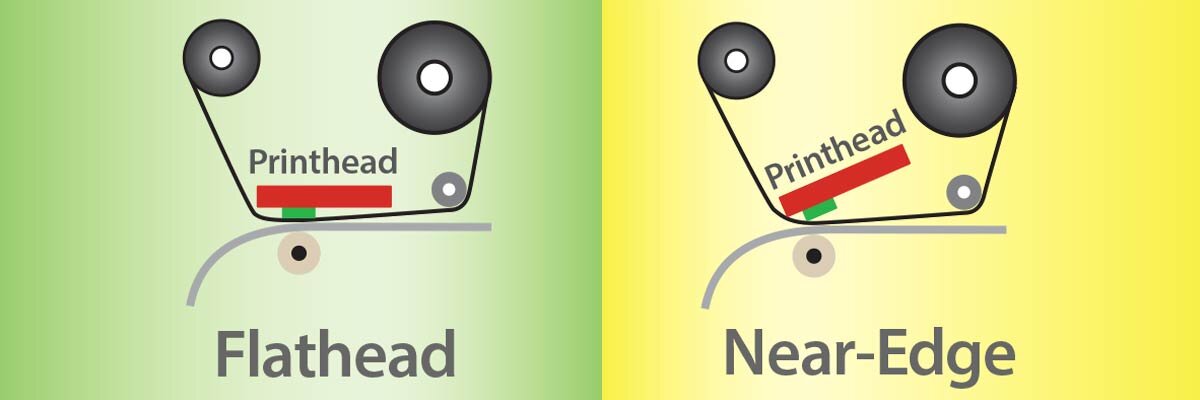

Near Edge and Flat Head Thermal Transfer printing both use the same fundamental process. Both sandwich a label or tag material against a wax/resin ribbon, and electronically heating diodes in a printhead to melt the ribbon against the substrate to create an image. Near Edge printing augments the basics design of thermal printing to achieve the following:

1. Much faster print speeds when used in flexible packaging printers

2. Printing on thicker and different material substrates

3. Saves ribbon by optimizing how it is fed under the printhead.

Flathead Thermal Transfer Process

The printhead is horizontal in flathead printing, and the heating components are in the middle of the printhead. Ink is transferred to the substrate as the ribbon passes over the heating elements. The “spent” ribbon is fed to a take-up reel inside the printer, and substrate, (labels or tags), are continuously fed to the front of the printer either one-at-a-time or continuously. The melted wax, transferred to the label, only requires seconds to solidify without smearing. Print resolution, or quality, in this process range from 203 dpi (dots per inch) to 600 dpi.

Printhead is fixed and horizontal to the substrate being printed.

Practical print speeds range from 6 ips to a maximum of 16 ips (inches per second). 600 DPI maximizes at 6 ips.

Prints on a range of paper, synthetic, vinyl and polypropylene stock material using Wax, Wax-Resin or Resin transfer ribbon.

Near-Edge Thermal Transfer Process

Near-edge printhead technology offers higher speed throughput at up to 16 ips, and some specialized printers even faster. Near Edge printing can also be termed as “corner edge” or “floating head” print technology. The near-edge print head is angled to the substrate, with the heating elements located at the edge of the printhead. This allows faster speeds. The substrate, (label, tag or package), only comes in contact with the ribbon as it passes under the printhead’s heating elements, which requires an instant transfer of ink. When compared to flathead printers, the distance between where an image is printed and where the ribbon and receiver separate is substantially shorter.

The floating printhead allows for a greater distance between the printhead and substrate, making near-edge printing the choice for printing on thick tag stock up to 0.22mm. Near-Edge printheads require more cleaning that flathead printheads because of less surface contact. We suggest cleaning after every roll of labels printed. Applications include high speed label printing, direct package printing, or printing on thick plastics like horticultural pot stakes.

The Print head is floating

The ribbon and substrate separate instantly after transfer

Can print thick substrates – up to .023mm thick.

Near-edge desktop printer models are are capable of printing 14+ ips. (Very fast speed up to 40+ inches per second, (ips), using high speed flexible packaging printers.)

Near edge printers feature a ribbon saver feature.

Only uses Wax/Resin or Resin Ribbons, black or color.

Special Thermal Transfer Ribbon Required for Near-Edge Printing

Near Edge Ribbons must contain a release layer which allows the ink to quickly release from the ribbon after melting, without the need to re-solidify. The unique ribbon chemistry limits ribbon type to wax/resin and resin black and color thermal transfer ribbon formulations. The maximum print resolution on near-edge printing is 203 dpi to 300 dpi.

Flathead Printers

Zebra

Sato

TSC

Honeywell, (Datamax and Intermec)

Citizen

Cab

Near-Edge Printers

Toshiba TEC

Datamax (limited models)

Avery Dennison

Sato (limited Models)

Thermal Transfer Overprinting

Another common type of printing that uses a near-edge printhead and thermal ribbon is called thermal transfer overprinting (TTO). These printers are assembled as part of inline production systems that print, time, date, and lot markings onto flexible packaging, prior to being filled. The most common example is bags of snacks and other food that requires dates. The speed of these printing systems can reach 25 to 40 ips.

Barcode Factory sells near-edge ribbons and printheads used in every major TTO printer. We manufacturer thermal ribbon specific to Markhem, VideoJet, Domino, Advanced Poly, as well as the ribbon specific to Toshiba Near-Edge printers. We also sell the OEM manufacturer’s ribbons, but try the generic, as they are the same quality and much lower in cost.

Conclusion

Standard barcoding applications for shipping and labeling can be completed using a flathead thermal printer. Thicker substrate and flexible packaging require near-edge printing. Industries such as food packaging and horticulture are well served by near-edge printing. Contact a sales specialist to learn more, or if near-edge printing may be the solution you are looking for.