Linerless Thermal Label Advantages

No label liner, no thermal ribbon - a sleek and fast way to print labels.

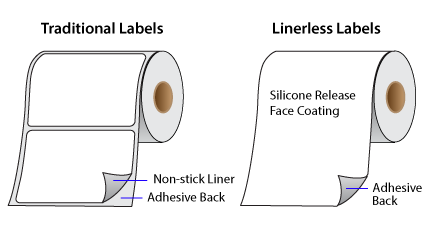

Unlike traditional labels that are made using a face stock, adhesive and silicone liner, Linerless labels eliminate the need for a liner by putting a silicone release coating on the face of the entire label. It’s important to note that Linerless labels are manufactured as a continuous roll.

The use form is much like a receipt paper, the more you purchase, the longer the receipt. Linerless labels do require a special printer that is equipped with a high-silicone release platen that will not allow the glue residue to stick to it.

Applications for linerless labels

Fast food in all of its forms, and the increase in to-go orders have nearly demanded these printers and labels for marking prepared foods, drinks. Others have taken to making this their final customer receipt. Common information includes: Customer name, Order number and specifics, Order date, time and price.

Grocery and Retail in all of its forms, use linerless in their deli’s, meat department, bakeries hot food sales. Alternatively price-changing on shelves and produce/ product can be done using a mobile printer at the point of application, offering the most convenient solution.

Warehouse and transportation are constantly looking for time and material saving measures. Direct thermal labels, which are linerless labels, are the most commonly used as shipping labels. Taking a label from the printer directly onto the box or bin, either by hand or automatically is as fast as it can get. Packing houses for fresh produce are also replacing their printers and label media in light of the savings.

Linerless Labels

Linerless Adhesive Options

The degree of linerless label stickiness, is determined by the adhesive pattern on the back of each label roll. Patterns of adhesive vary from diamond-shape to multiple stripes and even one single stripe of adhesive for a very light but effective adhesion; these are considered re-positionable. Multiple color rolls are also available for an fast identification and separation option.

The Future of Linerless labels

Linerless media costs the same as, if not slightly more than, regular thermal labels. The thermal printers required to print these labels are slightly more expensive than standard thermal label printers on their own and most models are mobile or small desktop sizes.

Simply removing the liner boosts print and application productivity, improves workplace safety, saves money, and lowers waste production with a biodegradable product.

Linerless self adhesive labels have these main benefits:

You can fit twice as many labels on a roll because there’s no liner to take up half the space. This means you will replace label rolls half as often, which equates to less down time.

Shipping costs are reduced by half and you will take up half the space to store.

Less environmental impact - You will not have to throw away the liners, reducing landfill waste and disposal cost.

Your workplace will be safer. Liners are silicone based which makes them slippery and a danger if left on the floor.